187 views admin 2025-09-28

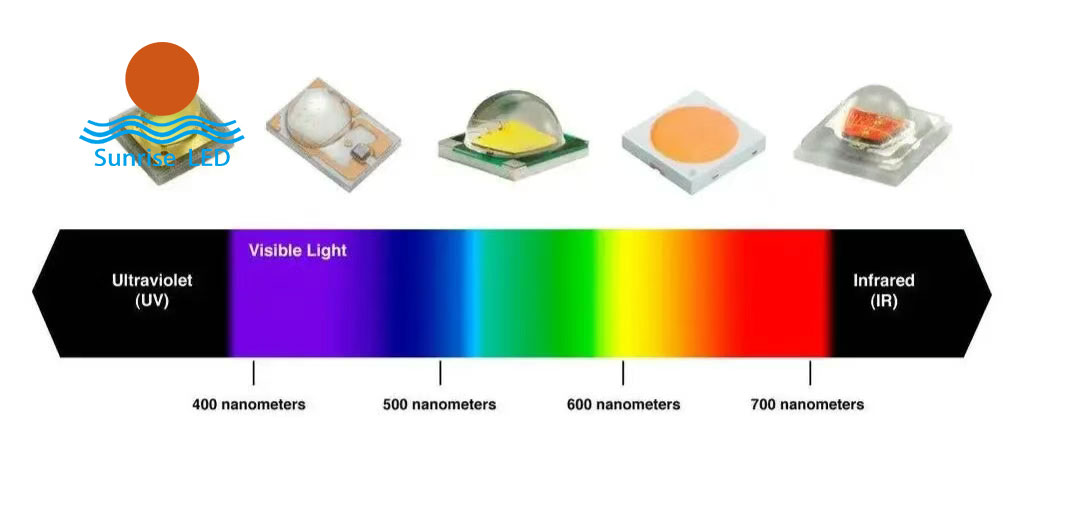

Wavelength Deviation: Variations in the wavelength of red, green, and blue lamps from the same batch (e.g., standard red wavelength is 620-630nm; if some lamps are around 610nm, they appear orange) cause mixed colors to deviate from the standard.

Brightness Difference: Inconsistent luminous intensity (cd/m²) among lamps of the same color. For example, some green lamps being brighter can make the overall picture appear greenish.

Viewing Angle Deviation: Differences in the viewing angles of the lamps cause an imbalance in the mixing ratio of the three colors from different viewing positions, resulting in "viewing angle color cast."

Different Decay Rates: Red, green, and blue LEDs have different lifespans and decay rates (blue typically decays fastest). After prolonged use, the brightness ratio of the three colors becomes unbalanced, causing an overall color cast.

LED Failure: Individual LEDs failing ("dead pixels" - not lighting up) or leaking current (abnormal brightness) create dark spots, bright spots, or localized color cast areas on the screen.

Unstable Current Output: Drive ICs (like constant current ICs) are crucial for controlling LED current. If ICs age, overheat, or are of poor quality, output current fluctuates, causing LED brightness to vary and leading to color drift.

Insufficient Grayscale Levels: Low-end drive ICs with insufficient grayscale levels (e.g., below 16-bit) cannot achieve smooth color transitions, resulting in "color banding" or "color blocking," which looks impure.

Data Transmission Errors: Poor contact in the ribbon cables between the control card and driver boards, or excessive signal transmission distance (without signal boosters), can cause color data loss or corruption, leading to random stray colors.

Incorrect Control Parameters: Uncalibrated "white balance parameters" or "color gamut settings" within the control card. For instance, setting the red gain too high makes the overall picture reddish. A mismatch between the screen's color gamut setting and the signal source (e.g., signal is RGB, screen is set to YUV) also causes color deviation.

Fluctuations in the display's power supply output voltage or current (e.g., low voltage causing insufficient power for drive ICs, excessive current causing LED over-brightness) disrupt the brightness balance of the RGB LEDs, causing overall color cast or local color abnormalities.

Material or Process Variation: Inconsistent transmittance or dispersion characteristics of the mask (the protective layer over the LEDs) or lens can filter out light of certain wavelengths (e.g., a yellowish mask area causes displayed colors to shift warmer).

Stains or Scratches: Dust, oil, or scratches on the mask surface cause local light scattering, disrupting the mixing ratio of the three colors and creating "dirty colors" or local dimming.

Displays require "white balance calibration" during production to ensure red, green, and blue mix in proportion to produce pure white (standard white balance ratio approx. R:G:B ≈ 3:6:1). If uncalibrated, calibration parameters are mistakenly changed, or lamp decay over time invalidates the calibration, whites will appear off (e.g., bluish or reddish), affecting the purity of all colors (since all colors are based on the white balance reference).

When multiple LED modules are spliced together, differences in brightness or color temperature between modules (e.g., different white balance parameters) create visible "splicing line color cast," leading to uneven color across the entire screen.

Input Signal Issues: The input video/image signal itself might have impure colors (e.g., original footage has color cast, over-compression causes color distortion), or the signal source's color space (e.g., sRGB, DCI-P3) might not match the display, causing the screen to "faithfully reproduce" the distorted colors.

Strong Ambient Light: Direct sunlight or strong spotlights hitting the screen add to the screen's own emitted light, altering the color ratio perceived by the human eye (e.g., blue is weakened under strong light, making the picture warmer). If the ambient light itself is impure (e.g., yellow lighting), it also "contaminates" the displayed color.

Harsh Environments: High temperature and humidity accelerate the aging of LEDs and drive ICs, worsening parameter drift. Dust accumulating inside modules on LED surfaces causes light scattering, reducing color saturation.

Localized Color Cast/Stray Colors: Prioritize checking LEDs (damaged/aged?), drive ICs (overheating?), and ribbon cables (poor contact?) in the affected area.

Overall Color Cast: Prioritize checking white balance parameters, control card color gamut settings, and power supply stability.

Color Cast Varies with Viewing Angle: Likely due to poor LED viewing angle consistency or mask optical characteristics.

At present, the naked eye 3D large screen market is hot, and 3D technology is also known as 3D di...

Sunrise’s p2.604 curved LED display lights up under the Eiffel Tower Sunri...

Concert activities are popular in the United States, and sunrise’s products have been wide...

Sunrise 264 square meters Galaxy 3115 series mesh led facade in Armenia Sun...

Doris, as a new salesman, won three orders in two months. It’s great. Jack, the bu...

640w and 800W full spectrum led grow light It can be folded for convenient transportatio...

The latest project, Saudi Arabia LED MESH FACADE. Ultra-high brightness, ultra-light LED display ...