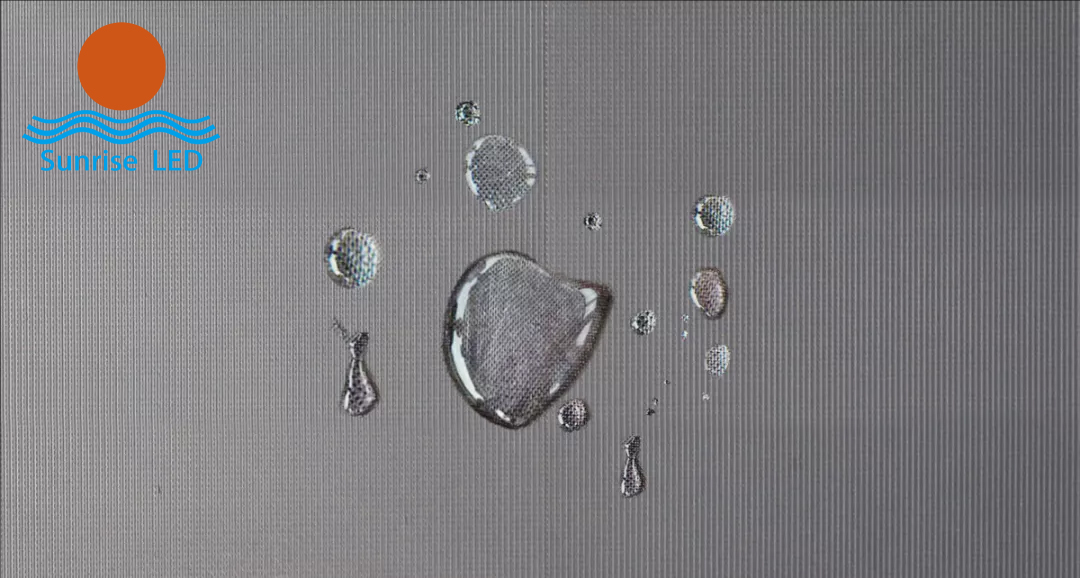

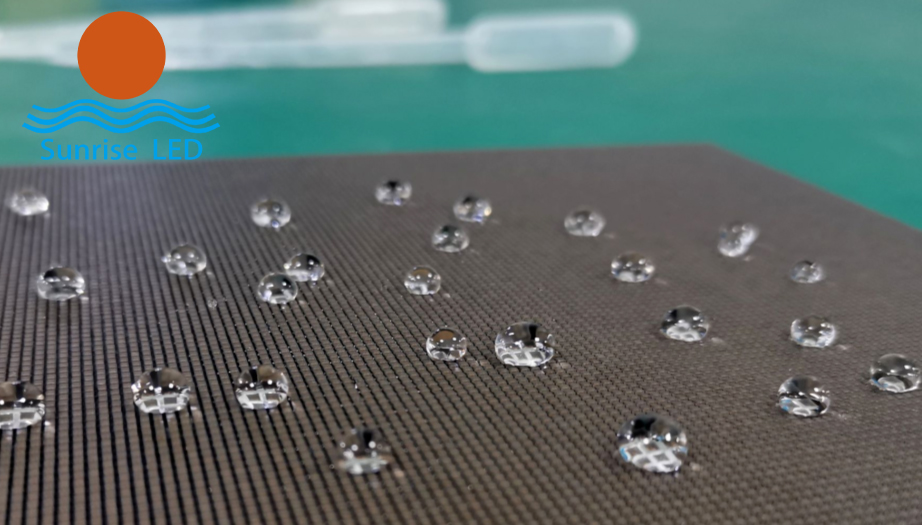

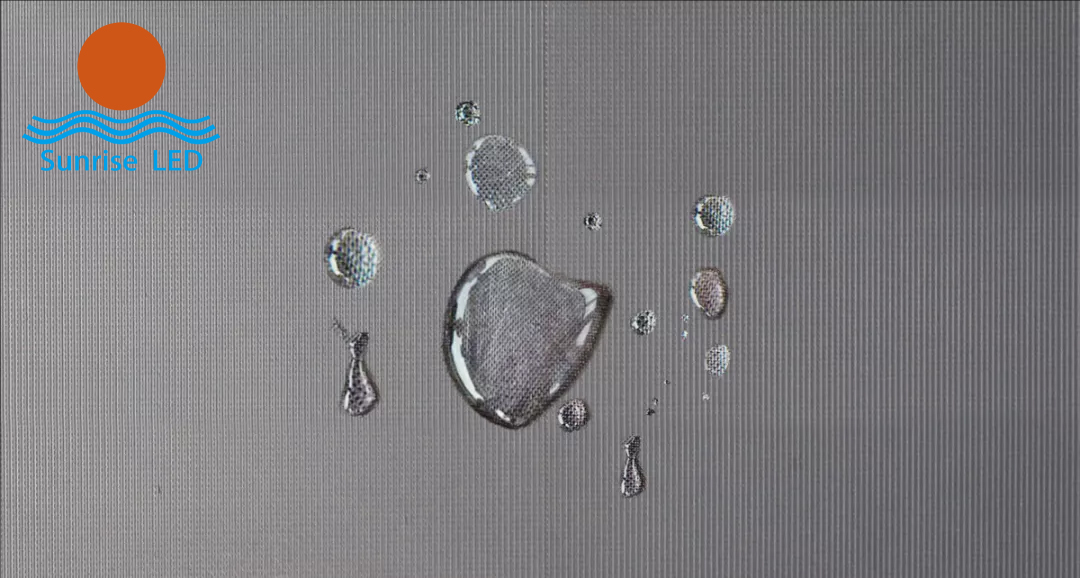

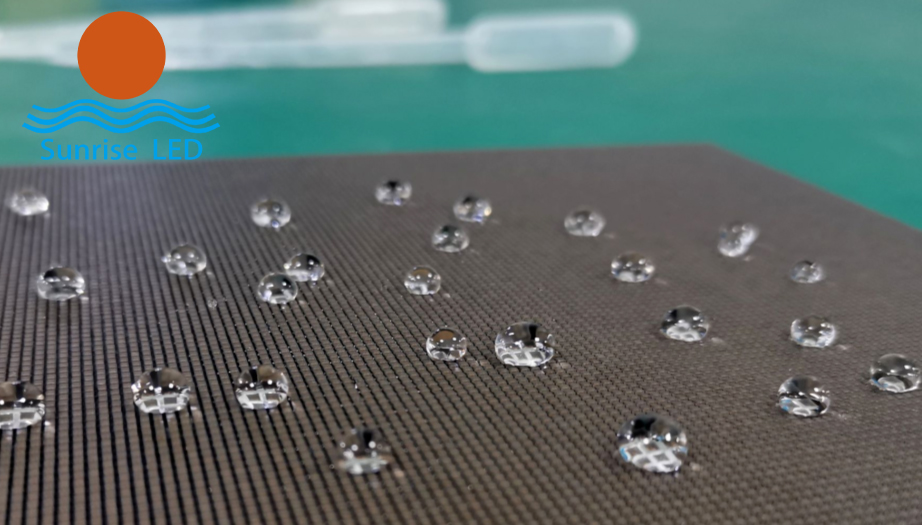

- Moisture protection for LED displays is centered on actual application scenarios (indoor/outdoor/rental) and the entire life cycle (installation/use/storage/idleness). All measures are standardized practical methods commonly used in the industry, with a core control target of 30%-60%RH ambient humidity and a core protection logic of physical sealing to block moisture + active humidity control and discharge + regular ventilation to prevent condensation.

- Outdoor LED Displays

- Outdoor displays are the focus of moisture protection. All measures are based on actual engineering installation specifications, with no fictitious design-level solutions:

- Structural sealing practice: Industrial-grade silicone sealing strips are used for the display frame and cabinet splicing joints, and neutral weather-resistant sealant is applied to the splicing gaps. Power boxes and junction boxes are independently sealed, waterproof rubber rings are added to cover plates, and screw holes are sealed with glue to prevent water vapor from intruding through gaps.

- Cable and interface protection: Waterproof aviation connectors are used for power and signal cables, and drip bends are made for outdoor wiring to prevent rainwater from flowing into the display along the cables. Wall holes for through-wall cables are double-sealed with fire clay and sealant with no gaps left.

- Drainage design implementation: Drainage holes are reserved at the bottom of the display cabinet, and the entire display is installed to tilt outward to allow internal condensed water and a small amount of seepage to drain naturally. A ventilation gap is reserved at the back of the display to avoid water vapor accumulation caused by direct contact with the wall.

- Basic auxiliary material protection: Steel structure brackets for display installation are anti-corrosively treated with hot-dip galvanizing/coating to prevent rust water from intruding into the display due to bracket rusting. A waterproof awning can be installed at the back of the display to reduce direct rain scouring and dew condensation.

- Indoor LED Displays

- Indoor displays have no risk of outdoor rain exposure, and moisture protection mainly focuses on preventing condensation from high ambient humidity and water vapor accumulation, with all methods directly operable on-site:

- Moisture avoidance requirements for installation: The display is placed away from water sources and green plant areas, and not installed in shaded positions with wall moisture seepage. A 20-30cm ventilation gap is reserved between the display and the wall, and an access panel is reserved for ceiling-mounted displays to ensure air circulation at the back.

- Basic sealing treatment: Basic sealant is applied to the display splicing gaps and power interfaces to prevent indoor dust with water vapor from adhering to the surface of components. Exposed flat cables and connectors are sleeved with insulating waterproof sleeves to avoid condensation dripping onto the circuit.

- mbient humidity control practice: During the southern China's damp season and plum rain season, close doors and windows to prevent outdoor high-humidity air from entering, and turn on the air conditioner dehumidification mode or industrial dehumidifier to control humidity within 60%RH. Open windows for natural ventilation on sunny days to accelerate the discharge of indoor water vapor.

- Due to frequent disassembly, transportation and site replacement, moisture protection for rental displays is mainly based on temporary sealing and rapid moisture discharge, all of which are common practical methods in the rental industry:

Transportation and storage sealing: Disassembled display modules and cabinets are immediately put into moisture-proof sealed bags and hard sealed boxes to avoid contact with rain and dew during transportation. Temporary stacking sites need to be elevated to keep away from ground moisture seepage.

On-site installation protection: For temporarily built outdoor rental displays, install a simple rain awning, apply temporary glue to seal the splicing joints, and wrap cable interfaces with waterproof tape for sealing. Suspend disassembly and assembly during rainy construction, and cover the installed display as a whole with waterproof cloth.

Immediate post-use treatment: Wipe off water stains and dew on the display surface immediately after use, disassemble and assemble the display only after it has cooled naturally, and perform sealing treatment in a timely manner after disassembly and assembly without stacking it exposed.

Emergency Treatment: Correct Operation When the Display is Damaged by Moisture/Water Ingress

If the display is accidentally affected by moisture (internal condensation) or has a small amount of water ingress, do not power it on directly. Follow the following industry universal steps to avoid short circuits and burning of components:

Power off and ventilate: Cut off all power immediately, open the back cover and junction box of the display, move it to a dry and ventilated place for natural air drying, or use an industrial fan (cold air) to accelerate air circulation. Do not blow directly with a heat gun.

Dehumidify and detect: After air drying, use a dehumidifier to continuously dehumidify the inside of the display for 4-6 hours, then use a multimeter to detect circuit on-off and insulation resistance to confirm no short circuit and no residual water vapor.

Test and start up: After passing the test, first turn on the power module alone for 30 minutes of standby, then turn on the display step by step, run a low-brightness test for 1 hour, and observe whether the display has faults such as distorted images, uneven brightness and dead LEDs. Restore normal use only if there is no abnormality.

Summary of Core Moisture Protection Practices

Outdoor displays: Sealant, waterproof connectors and drainage holes are the three indispensable elements, all of which are mandatory for engineering installation;

Indoor displays: The core measures are keeping away from high-humidity sources, reserving ventilation gaps and dehumidifying during the damp season, with no need for excessive sealing;

All displays: Power-on moisture removal is the most economical and effective method, which should be adhered to daily;

Moisture/water ingress: Power off first, then air dry, and finally detect. Direct power-on is strictly prohibited, which is a hard operational standard in the industry.