Comprehensive Guide to LED Displays

86 views admin 2025-12-26

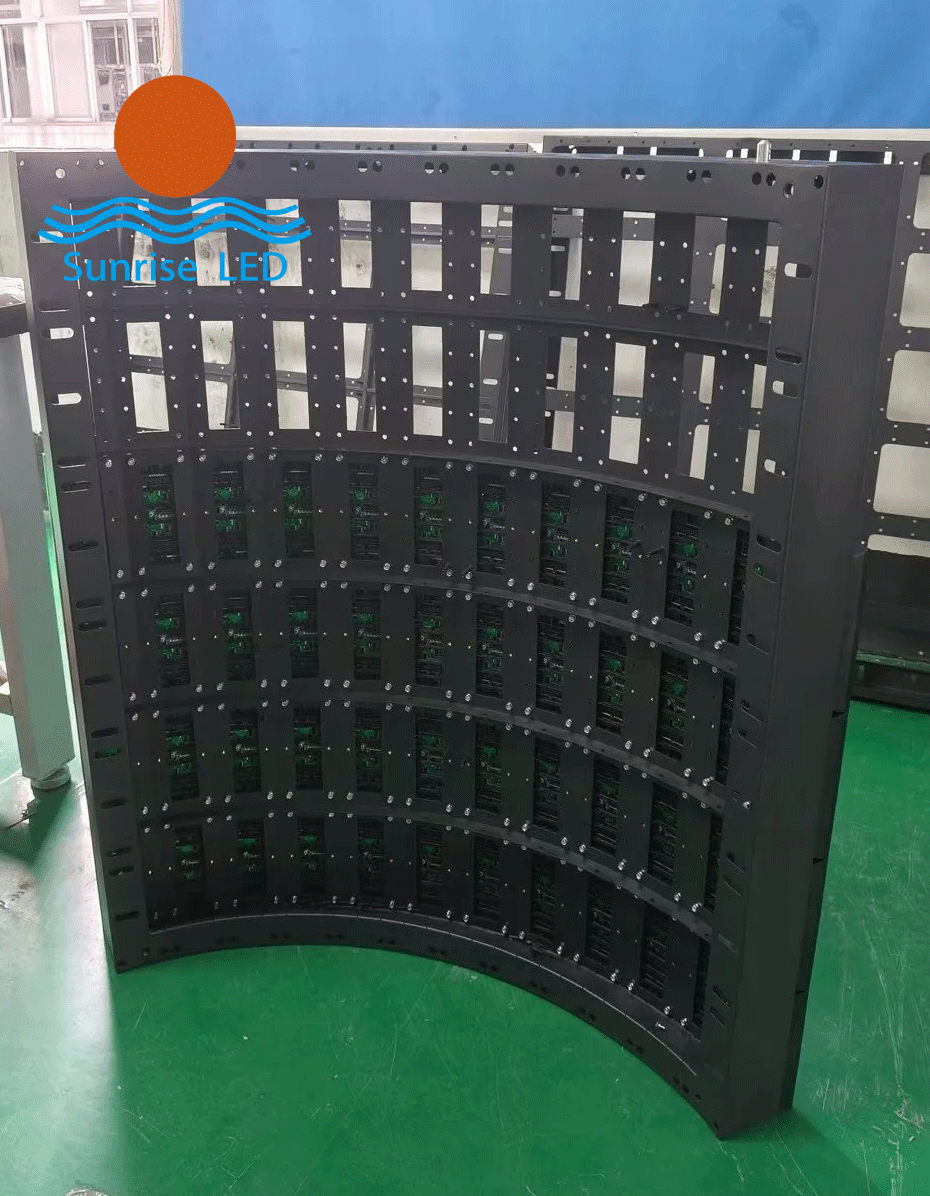

- Currently, the curved display surface of a curved LED screen is constructed primarily by means of arc-shaped LED cabinets or frame structures. The steel structure is custom-designed according to the specifications of the display screen.

-

In the past, the module mounting surface of an arc-shaped cabinet was bent into polygonal planes with 4–6 or more bends, and then square display modules were mounted on these bent surfaces to form a near-arc display surface. Multiple arc-shaped unit cabinets were then assembled together to create a large-area curved LED display.

-

For curved LED displays, using horizontal LED modules for assembly would lead to numerous issues, such as large assembly gaps, uneven screen curvature, and incompatibility with large-radius curvature applications. Therefore, to ensure smooth curvature, vertical assembly of LED modules is adopted, which achieves better surface smoothness and allows for easier assembly of large-radius curved LED displays. Nowadays, manufacturers have launched flexible LED modules, making the design and installation of curved screens more convenient.

- In general practical applications, externally curved LED screens are relatively more common.

- Traditionally, there were three main manufacturing methods:

- For arcs with a radius larger than 1 meter: The LED cabinets are made into vertical strips and assembled directly.

- For arcs with a smaller radius: The cabinets need to be manufactured with curved shapes, and attention should be paid during the assembly of unit LED modules.

- For arcs with an even smaller radius (less than 0.5 meters): Customized unit modules must be produced. These units are made into vertical strips. In addition, the steel structure of the screen needs to be processed to form the required curve. At present, some structural manufacturers also provide mechanical arc rolling services, supplying factory-preformed curved structures that can be directly used, which further simplifies the process.

- Image dimension of curved LED screen: Length × Width (Height) = L × W

- Image width (W) of curved LED screen: Refers to the height of the displayed image.

- Image length (L) of curved LED screen: Refers to the length of the displayed image.

The image length (L) of a curved LED screen can be initially determined based on the circumference of the circle or arc. Dividing this circumference by the length of a single module gives the total number of modules required.

For circular LED screens, it is advisable to determine the number of modules per row as an integer multiple of 2, 3, 4, 5, or 6 (this facilitates cabinet division and mass production). The typical draft angle of an LED module is 2 degrees, meaning a single module covers an arc of 4 degrees. Based on this, approximately 92 modules are needed to form a perfect circular screen. The minimum number of modules should not be less than 60.

Once the number of modules per row for a curved screen is determined, the image length (L) can be calculated using the formula below:

Image length (L) of curved LED screen = Number of modules × Length of a single module

The total image area (A) of the curved LED screen is calculated as:

Image area (A) of curved LED screen = L × W